Laser Cutting and Engraving in Delhi

It is usually used for industrial technical applications but also beginning to be accepted by schools, small businesses, and hobbyists. Laser cutting operates by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are utilised to direct the material or the laser beam generated. A standard commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is aimed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are employed to cut flat-sheet material as well as structural and piping materials.

How does laser cutting work?

Laser cutting is a thermal separation process. Throughout the process, predetermined geometries are traversed and cut by the laser beam. As with engraving, a broad variety of materials can be used. A vector-based file (lines and curves of geometry) is the source for the cutting process. This process is used to make shapes (such as letters, signs and tags) as well as applications that have earlier been engraved

Laser Engraving

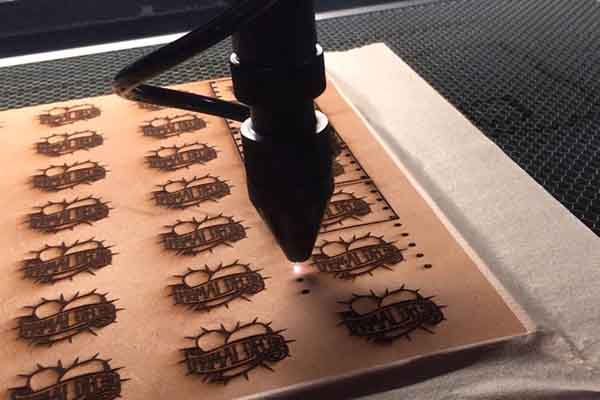

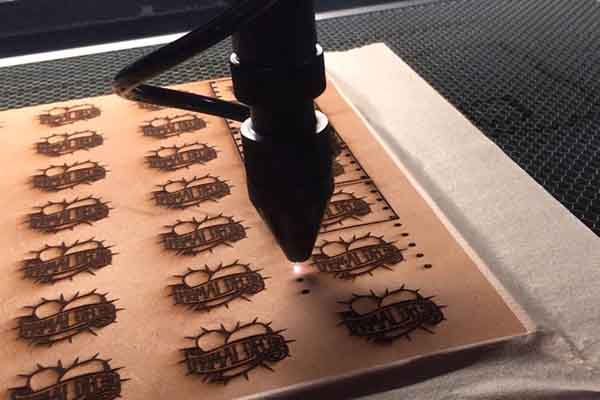

Laser Engraving (or Laser Etching) is a Subtractive Manufacturing technique, that uses a laser beam to change the surface of an object.

This process is often used to create images on the material, that may be seen at eye level. To do so, the laser forms high heat that will vaporize the matter, thus exposing cavities that will form the final image. This method is swift, as the material is removed with each pulse of the laser. The depth of the marks is regulated by the number of times the laser beam is passing on the material.

How does laser engraving work?

During the process of laser engraving, the laser prepares a shape, graphic or picture (e.g. a JPG or PNG) on a wide range of materials. The laser travels horizontally along the individual lines of the engraving, and the material being engraved is removed point by point, line by line. This method is called grid engraving.

Between other things, surfaces or shapes can be etched using this method, including photos, pictures, logos, inlays, fine to thick lettering, and stamps, to name a few.

Difference between a laser cutter and engraver?

The principal difference between specified cutting and engraving machines is the laser machine lens.

The lens focal length is smaller in the laser engraving machine to give a finer spot size when working on materials. This yields a higher quality when engraving items such as photographic images.

The longer focal length lens on the laser cutting machines is more sophisticated of focus height variations and produces less taper in the cut edge. This is more appropriate for cutting thicker materials, where a cutting lens would reduce the angle of laser cut sloped edges. This would only normally be apparent on materials with a relatively large depth to them, such as 20mm acrylic or thicker.

It is usually used for industrial technical applications but also beginning to be accepted by schools, small businesses, and hobbyists. Laser cutting operates by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are utilised to direct the material or the laser beam generated. A standard commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is aimed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are employed to cut flat-sheet material as well as structural and piping materials.

It is usually used for industrial technical applications but also beginning to be accepted by schools, small businesses, and hobbyists. Laser cutting operates by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are utilised to direct the material or the laser beam generated. A standard commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is aimed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are employed to cut flat-sheet material as well as structural and piping materials.

Laser Engraving (or Laser Etching) is a Subtractive Manufacturing technique, that uses a laser beam to change the surface of an object.

This process is often used to create images on the material, that may be seen at eye level. To do so, the laser forms high heat that will vaporize the matter, thus exposing cavities that will form the final image. This method is swift, as the material is removed with each pulse of the laser. The depth of the marks is regulated by the number of times the laser beam is passing on the material.

Laser Engraving (or Laser Etching) is a Subtractive Manufacturing technique, that uses a laser beam to change the surface of an object.

This process is often used to create images on the material, that may be seen at eye level. To do so, the laser forms high heat that will vaporize the matter, thus exposing cavities that will form the final image. This method is swift, as the material is removed with each pulse of the laser. The depth of the marks is regulated by the number of times the laser beam is passing on the material.