Printing Techniques that mostly used

In this article, you will learn about printing techniques. Printing is a form of reproduction of text and images in existence since ancient times. The print industry has made huge headways from the ancient Chinese woodblock printing days.

Today, large scale printing is done using a printing press while small scale printing is done using digital printers. Here below we use several printing techniques in printing press in delhi :

1. Flexo Printing

Termed flexography or simply flex, this is done using a flexible relief plate. It can be utilised to print on any material like plastic, cellophane, metallic films, and of course, paper. It is generally used for printing on the non-porous materials used in food package industries.

This includes multiple processes like plate making, mounting and then printing. Flex has the benefit of being able to use a wide range of inks. This makes it a favoured choice for printing on many different materials like brown paper, plastic, foil, acetate film and a few other materials used for packaging.

2. Offset Printing

In this printing technique, the inked image is offset from a plate to a rubber blanket and moreover on to the printing surface. This is used very usually in combination with the lithographic printing process.

Used in many well-known applications, namely newspapers, magazines, stationery, brochures and books, this is the most economically befitted for large volume high-quality printing.

Other services are quick, easy production of the printing plates, the extended lifespan of the printing plates and the ability to adjust the ink quantity in the fountain roller with the screw keys.

3. Screen Printing

In screen printing, a mesh or screen is employed to transfer the ink onto the substrate, by blocking off areas using a blocking stencil. The screen or mesh can be formed of any synthetic polymer like nylon.

This is also recommended as silk-screen, serigraphy, and serigraph printing. It can be practised for printing on materials like paper, textiles, glass, wood, metal and even ceramics. Used most regularly in garments, it is also seen in clock and

4. UV Printing

A method of digital printing, UV printing as indicated by the name, uses ultra-violet lights to dry the ink as the printing happens. While the printing surface is classified with ink from the printer, UV lights uniquely designed to instantly dry the ink follow it.

The benefits that UV printing have is that these prints have a high amount of resistance to fading and are weather resistant too. It is also a more environmentally friendly process. It can be applied on more surfaces like wood, metal, hand-made canvas, CDs, concrete, plastic and even ceramic tiles. It also accumulates time as well as electricity.

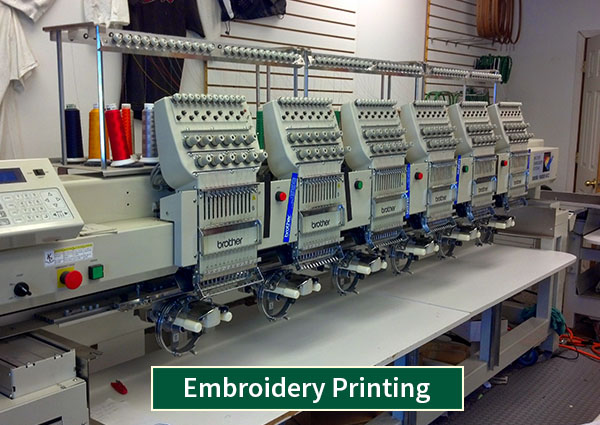

5. Embroidery Printing

Aside from screen printing, embroidery printing is the other most traditional method used for garments. Going by the meaning of embroidery, this includes weaving design with the help of a needle and thread. These are used to bring in elaborate designs on the apparel using either direct or patch embroidery techniques.

These are often used in printing logos on shirts, while also used on caps, hats, jackets, sweatshirts and even bags. Different factors, including the number of stitches, colors used and the place where the embroidery is done, conclude the cost of this printing.

6. Engraving

Engraving is a very primitive printing technique in which raised areas are created for printing images like those on a business card or letterhead. Thermographic printing too produces the same effect. This system has been used in jewellery making from ancient times. It can be done using hand or machines. Superior computer-aided engraving is now used, mostly in the making of diamond-based jewellery.

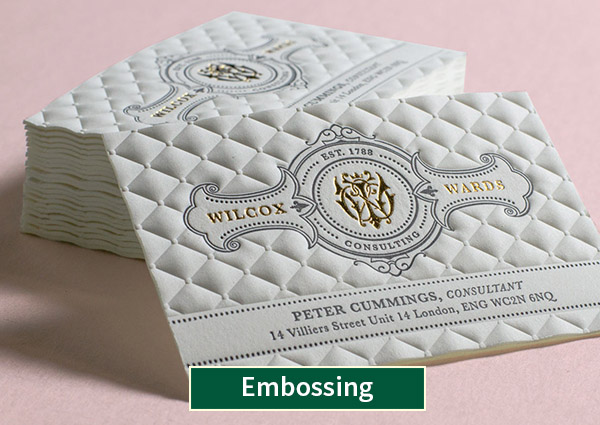

7. Embossing

This is a printing technique used to create a three-dimensional design by pushing it onto a paper or cardstock. It can be used to create logo designs or text. The embossed design is seen raised from the enclosing areas. It is used in places where you need to make an opinion literally, like on your invitations, folders, business cards, certificates, brochures etc.

8. Digital Printing

A primary result of the technological advances, digital printing designates printing directly to a printing surface using a digital-based image. Most professional printing is done using this method.

This is normally slightly costlier than the traditional printing techniques, but saves time, is highly customizable and can be produced on demand. The cost is countered by the time and labour factor and large print runs can be accomplished at a low price. This is one of the most familiar methods nowadays.

Well, this was the end of the article of Printing Techniques that mostly used. If you liked this article, we request you to please share it in your circles so that others can benefit from this too.